The offshore sector utilises various types of electronic instruments and controls such as oil & gas remote monitoring systems to process and analyse oilfield data, leak detection and asset monitoring. Offshore electronics and instrumentation systems help to ensure safety and environmental compliance, as well as improve the efficiency of operations.

Discover top suppliers of offshore electronics and control instrumentation solutions

Offshore Technology has listed leading suppliers of oil and gas measurement and control solutions, oil & gas remote monitoring systems, control and instrumentation systems, accelerometers and sensing products, based on its intel, insights and decades-long experience in the sector.

The list includes suppliers of oil field gas detectors, flow control valves and actuators, oil field water analysis solutions, oil and gas metering and regulating systems, control and ultrasonic flow meters and pig detectors, level control instrumentation, and data loggers and wireline electronics.

The information contained within the download document is designed for offshore control and instrumentation engineers, planning engineers, project engineer officers, senior control engineers and testing and quality engineers.

The download contains detailed information on the suppliers and their product lines, alongside contact details to aid your purchasing decisions.

See Also:

Applications of offshore electronics and control instrumentation systems

Electronics and control instrumentation systems are used to perform various functions in the oil and gas industry. Some of the most common applications are:

- Real-time condition and asset monitoring

- Oil field water analysis

- Gas and flame leak detection

- Predictive maintenance, and

- Fault detection

Choosing the right offshore instrumentation systems

The tough operating conditions of offshore oil and gas developments call for selecting reliable and sturdy instrumentation systems. Operating and environmental conditions including exposure to chemicals, extreme heat and cold can damage the sensors of equipment such as oil & gas remote monitoring systems and oil field gas detectors.

Performance characteristics such as accuracy, sensitivity, screen type and resolution, apart from maintenance requirements that include regular calibration are some of the factors that need to be considered when selecting instrumentation systems.

Uses of oil and gas remote monitoring systems

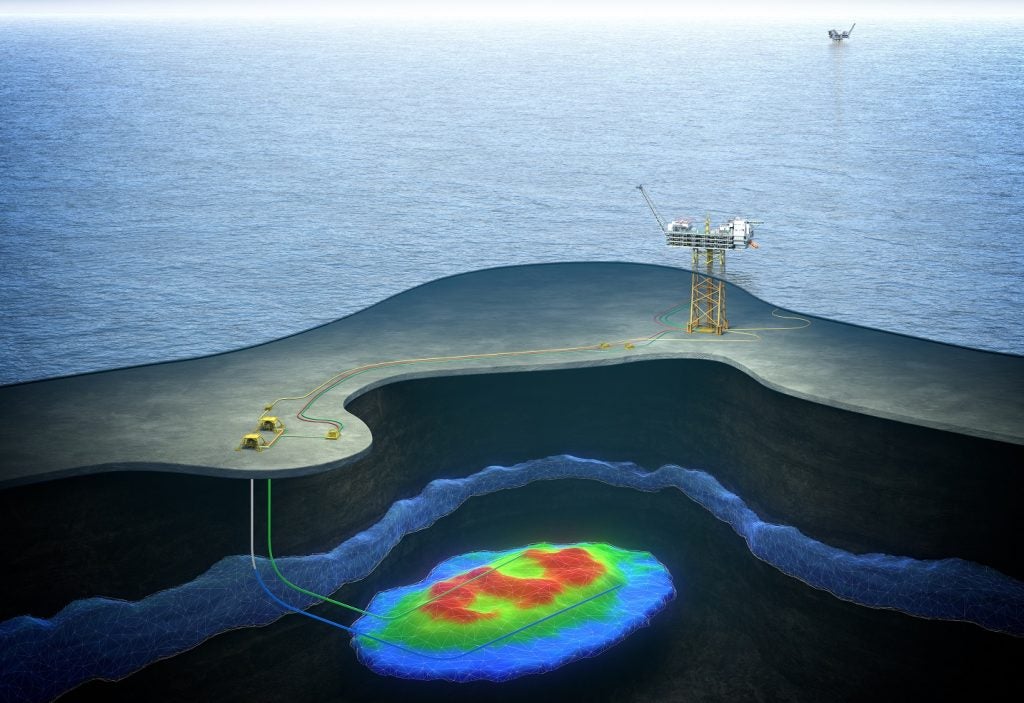

Offshore oil and gas development fields and facilities often lie in remote and deepwater locations. Unmanned facilities are used in some cases, which require regular inspection and monitoring to ensure optimal performance.

Oil & gas remote monitoring systems can help in remotely monitoring the status and health of the facilities from onshore locations and verify the environmental and equipment conditions. They also help in scheduling and implementing maintenance activities.